Facilties

Welding Shops

DBMA has a very strong & dynamic Welding Training Infrastructure whose core strength is the quality of expertise and experience of the training team. We have 3 Welding Instructors all with long Industrial Experience besides necessary Qualifications & all are duly certified 6G Welders by DNV. We have machines for GTAW (TIG)/ GMAW (MIG)/ FCAW (Self & Gas Shielded)/ SAW (Submerged Arc), Arc Gouging, Plasma Cutting processes. SMAW (MMAW) is our Bread & butter and we train a large number of trainees in this process each year. We train welders in all the above processes in Fillet or Butt, in any position from 1 G to 6 G/ 6 GR and on metals such as C.S., S.S., High Tensile Steel, Aluminum, Copper, Brass etc. Our Training is Short, Intensive and with a Specific Training Objective with an Evaluation Test at the end. Training is conducted with One Machine per Trainee. Along with Electric Arc Welding, we also train in Gas Welding, Brazing and Gas Cutting using Oxygen /Fuel / Acetylene Gas and handheld Torches besides PUG Machines.

Machine Shop

Our workshops are large, airy and well equipped for training purposes. We have 14 Nos. Italian & Indian Lathe Machines, available for Regular Training Needs. We also have Pedestal Grinders, Pillar Drill Machines, Gang Drilling Machine, Radial Drill, Shapers, Milling Machines, Grinding Machines and Power Hacksaws. We conduct training mainly on Lathe but other machining operations such as Milling, Grinding etc. are also taught, if required. Trainees work on one machine per trainee basis (for Lathe) and thus get confidence of working on machines and use of the precision instruments for producing as per drawing or as per sample. We conduct training for Engineers, Fitters and Cadets besides trainee and experienced workmen (refresher or skills enhancement courses) from many shipping industries. Our Training is Short, Intensive and with a Specific Training Objective with an Evaluation Test at the end.

14 Italian & Indian Lathe Machines

Pedestal Grinders, Pillar Drill Machines, Gang Drilling Machine, Radial Drill, Shapers, Milling Machines, Grinding Machines and Power Hacksaws

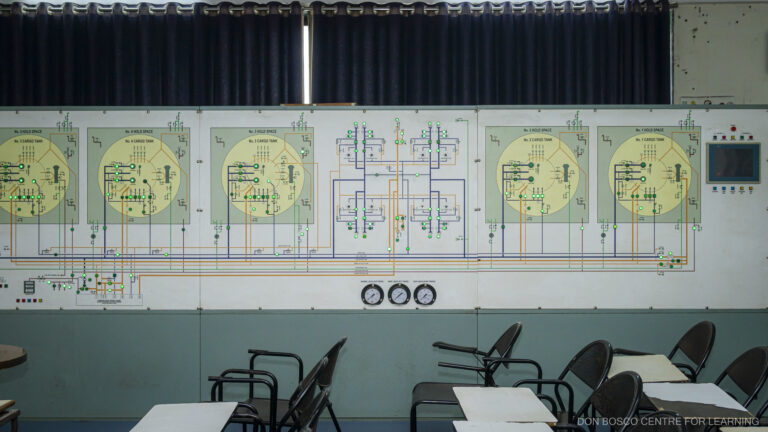

Classrooms / Library / E Lab

Adequate Classrooms, Standard Training Facilities with Audio Visual Aids are available for each class. The Library has a sizable collection of relevant educational and reference books.

Safety & Emergency

Safety and its practice form an integral part of all training and working at DBMA. We follow the Best Practices in Personal Safety in Workshops and in Training. » All the required personal safety equipment is always provided, and our safety record has been excellent (0% serious casualty). » All the stakeholders of our academy including trainees are insured to a sum of Maximum of Rs. 2 lakhs against any accident within the campus. » A first-aid box is available inside all workshops and medical aid in the form of a doctor or nursing homes/hospitals are located near the campus for providing Emergency Medical assistance at any time. » All essential safety features are installed in the machine shop and welding shop. Fire fighting equipment is also at hand if required.

Air-Conditioned Dormitory

Air-Conditioned dormitories with Bunk Beds and locker facility are available.

Basic Electrical / Electronics Lab

We have a spacious Electrical & Instrumentation Laboratory cum Workshop. We train right from Trainee Electricians, Engineering Cadets/ Electrical Fitters to Senior Engineers and other professionals from Shipping Companies and Shore Industries. We conduct Training Courses in Basic & Advanced Electrical and Electronics Technology. We have qualified Trainers and Assistants who cater to these courses based on Installation, Usage & Maintenance functions.

Scaffolding and Staging Training / Rigging Training

We impart Training in Working at Heights by putting up Scaffolding. Sometimes, the Scaffolding is also called Staging. We have the necessary material and space available in house to carry out these courses. The training is imparted for persons working at different levels of responsibility.

Safe Hydroblasting

We training in Safe Hydroblasting in Theory & Practical. We have the necessary machinery and equipment and qualified staff to teach Safe Hydroblasting.

Assessment of Skills / Trade Tests

We carry out Assessment of various skills of the Technicians in several diverse vocations. This covers all standard processes and materials besides positions for Welding, besides Assessment of the candidates of various trades such as Pipe Fitters, Structural / Pipe/ Pressure Vessel Fabricators, Riggers, Scaffolders/ Stagers, Bench Fitters.

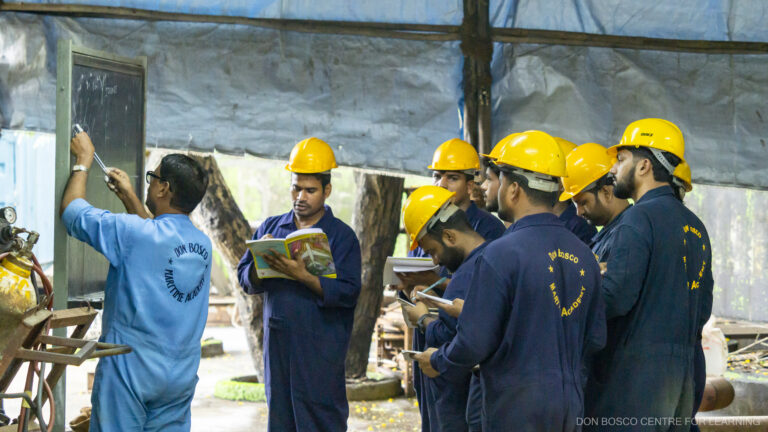

Marine Training

Marine Hands On Training Consists of Topics such as Mooring, Rigging, Scaffolding, Pilot Ladder Operation, Fire Fighting, Entry into Enclosed Spaces, Hazardous Gases, Personal Safety, Carpentry, Plumbing, Wire & Fibre Ropes Maintenance, Basic Seamanship. ISM, ISPS, IOPP codes are also covered if required. These courses are usually tailor made and conducted as per companies requirements and for dedicated groups.

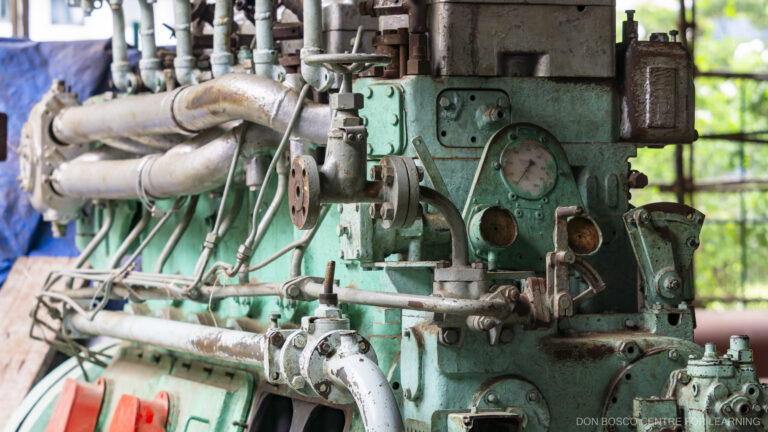

Overhaul of Marine Machinery

Now a days, Due to the quick turn around time, many Marine Engineers (and even Shipboard Fitters), do not get a chance to practice the overhauls of various marine machinery on board. We have several pieces of equipment, sourced from ships. These include Most of the standard Valves used on board Different types of Pumps used on Board Air & Refrigerant Compressors High Speed Purifiers (Centrifuges) Complete Generator Engines (4 stroke medium speed), including Cylinder head mountings, Turbocharger, Fuel Pump and Bearings Important Parts of Main Engine (2 stroke slow speed) Steering Gear Oily Water Separator Fresh water Generator Incinerator Plate Type and Shell & Tube Type Heat Exchangers The practice includes hands on dismantling and reassembly procedures. This is handled by our Marine Engineering Faculty and assisted by our Marine Fitters. Appropriate tools (including Hydraulic tools, torque wrenches) are used, as necessary. Though primarily brought for Training of Mariners this equipment is also useful for Process and similar Industries.

Pipe / Structural / Pressure Vessel Fabrication / Hand & Power Tools (Fitting) / Plumbing

Our workshops and yard were originally started for Fitting Shop (Hand & Power Tools) Training, with the sponsorship from various shipyards and industries, these were upgraded to carry out Structural, Pipe & Pressure Vessel Fabrication Training in a yard. We also train in Plumbing in this yard besides a state of the art Plumbing Training Workshop developed and available in our campus. We have all the necessary standard and Non Standard Training Equipment available. Following Operations taught during training: Marking, Gas Cutting, Grinding, Alignments / Set ups, Welding, Drilling, Assembly, Inspection (NDT tests), Test Erection of Scaffolds, Rigging & Safety such as Industrial Safety, Height Safety, Safety in Confined Spaces, Safety while handling Poisonous / Hazardous Gases / Liquids First Aid / Fire Fighting Many times these courses are company specific and decided after interaction with the industry